A Wedge Flow Meter is preferably applied in difficult-to-meter line fluids, like air entrained liquids, particular entrained liquids, high viscous liquids or slurry liquids, which are abrasive or fibrous.

It is also applicable for clean liquids, gas/air and steam. It consists of a measurement pipe with pressure taps in front and behind the flow element, a wedge restriction being welded into the measurement pipe from the top side.

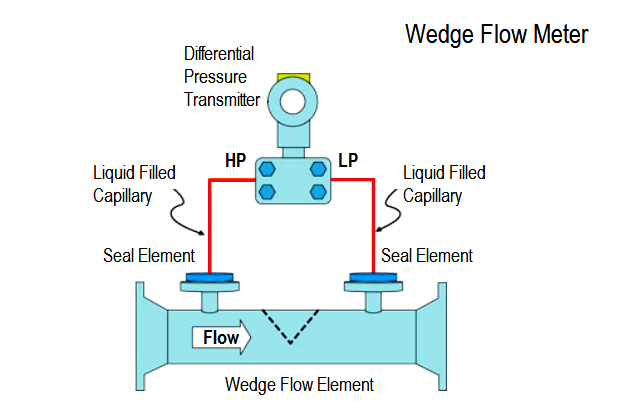

The pressure is being measured in front of the wedge (high or dynamic pressure side) and behind the wedge (static or low pressure side). By determining the difference of these two measurements, which is called the differential pressure, the volume flow of the fluid can be calculated, as all other characteristics of the measuring points are constant.

Wedge Flow Meter

As the wedge has the profile of an isosceles triangle, the form is the same from both sides. So the measurement is possible in both directions.

The line fluid is forced downward similar to a segmental orifice plate, but is guided along a slopping “wedge” shape rather than a sharp edge. The pressure taps are located upstream and downstream of the wedge and in all cases are equipped with sealed sensors.

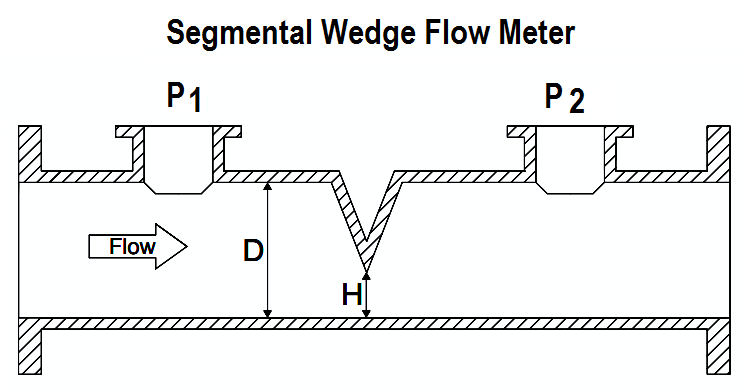

he differential pressure produced by the device is a function of the wedge segment opening (H) and the diameter of the body, “D” values as shown in below figure.

The calculations for compressible flow are similar but must take account to temperature and adiabatic expansion and compressibility factors.

Solids and other debris easily pass under the restriction of the wedge meter. The inherent ruggedness of the restriction resists damage to its measuring edge.