Can Insulation Thickness affect Thermowell U-Length ?

Thermowell Tip must be at least 2 mm immersed in Liquid whose temperature is to be measured (As per API 551)

In 2-phase service also it is recommended that Tip must be all the way up to Liquid phase for better measurement (PIP Std :-Temperature Measurement criteria)

A Standout of 6” is usually taken as rule of thumb and according the U-length calculated so that Thermowell tip is inserted at least 2 mm in process or more.(depending on client standards)

Now consider The Design Temperature got updated at the latter stages . At this point due to change in Temperature the Insulation thickness increased.

DOES THIS CHANGE IN INSULATION AFFECT THE THERMOWELL U-LENGTH?

Yes it does!!

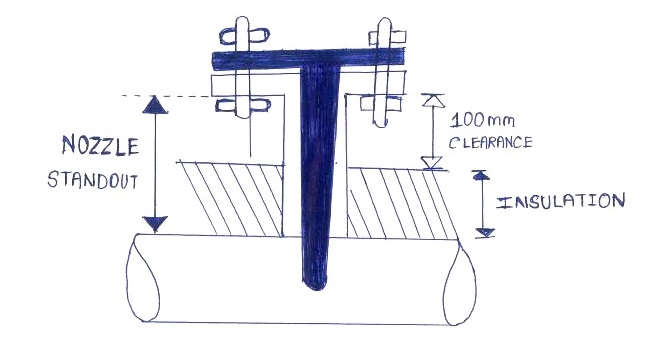

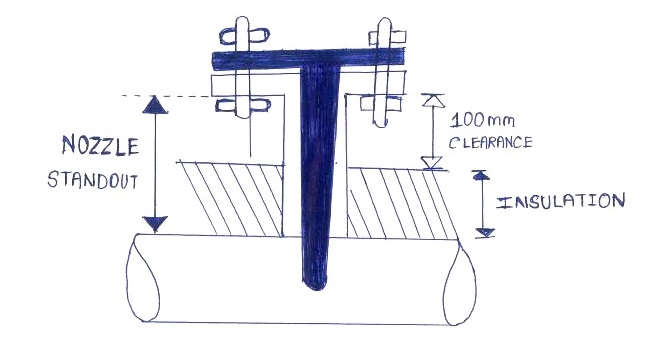

Good Engineering practice is that there has to be clearance of 100 mm (4 inches)between Insulation and the nozzle .This is followed in standard cases because whenever we need to remove the Thermowell and if insulation is all the way up to the nozzle then we will have to cut the insulation to get to the Bolts, Which is not a good practice.

Thermowell Insulation Thickness

Refer the diagram Below .

Good Engineering practice

Not so good engineering practice !!

Hence for Insulation between 0 to 50 mm we could have Standard standout of 150 mm ( 6 Inch)

But when insulation is 100 mm then standout must increase to 200 mm (8 inches)

Clearance (100 mm) = Standout (200 mm) – Insulation Thickness (100 mm)

Similarly if insulation is 150 mm then standout must increase to 250 mm (10 inches) so on and so forth.

So the Relation is as follows

Insulation (On pipe)>>affects>>Standout (Nozzle)>>affects>>U-length (Thermowell)

Hence we must cross verify at later stages before purchase that will standout affected due to insulation !!

Accordingly ensure whether the thermowell tip actually is in contact with process as per our requirement !!

Thanks for reading !!